Welding Link

Enter the automotive welding link. When the station carrying equipment such as the crane rail car transports the equipment to the next station. The vehicle type of the previous station transmits the vehicle type data to the next station through PLC. Or the vehicle type directly detect by the detection equipment of the next station. And the rail vehicle After it is in place. Read the model data recorded in the RFID Manufacturing Tags of the hanging rail car through RFID. And compare and confirm with the model data transmitted by the previous station through PLC. Or the data detect by the model sensor to ensure the correct model and prevent the wrong fixture switching or robots. The program number is wrongly called, resulting in a serious equipment collision accident, etc. The same situation can apply to the engine assembly line. The final assembly chain conveyor line and other stations that need to continuously confirm the model.

Coating Link

In car painting. The conveying equipment is a skid conveyor. And a RFID Manufacturing Tags install on each skid carrying an automobile body. In the whole production process, this tag runs with the workpiece. Forming a data that moves with the body and becomes a portable A “smart car body” that carries data. According to the different needs of production technology and management. RFID readers can be installed at the entrance and exit of the painting workshop. The fork of the workpiece logistics. And the entrance of important processes(such as painting room, drying room, storage area, etc.). Each on-site RFID reader/writer can complete the information collection of skid. Body information and spraying color and times, and send the information to the control center at the same time.

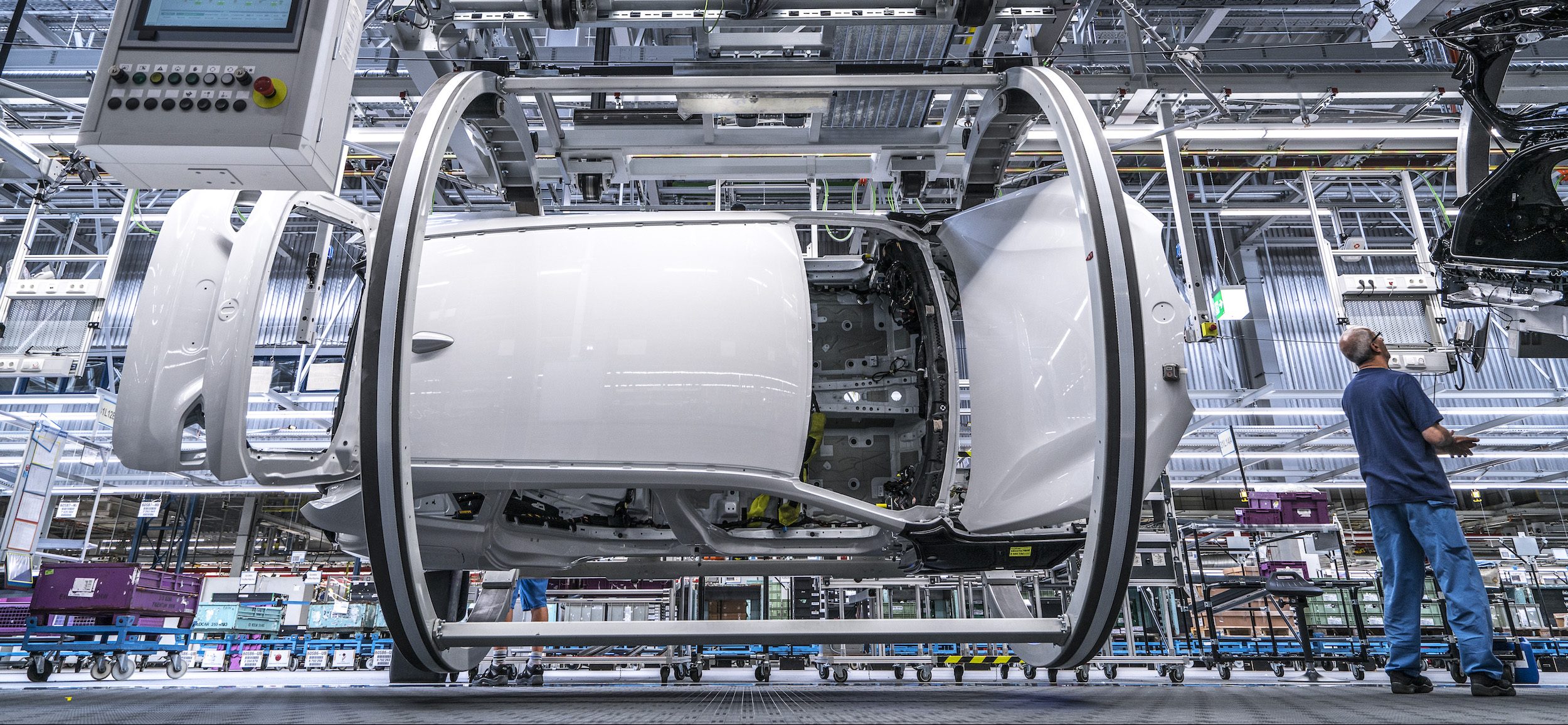

Final Assembly

in car assembly. RFID tags install on the hangers of the assembled vehicles (enter vehicle, location, serial number and other information). And then prepare the corresponding serial number for each assembled vehicle. RFID readers install at each station to ensure that. The car can complete the assembly task without error at each assembly line position. When the hanger carrying the assemble vehicle passes through the RFID reader. The reader automatically obtains the information in the tag and sends it to the central control system. The system collects the production data. Quality monitoring data and other information on the production line in real time. And then transmits the information. To material management, production scheduling, quality assurance and other relate departments. In this way, functions such as raw material supply, production scheduling, quality monitoring. And vehicle quality tracking can realize at the same time. And various disadvantages of manual operation can avoid it effectively.

Customization

Many BMW customers choose to order custom cars when purchasing a car. So each car needs to reassemble or reconfigure according to the customer’s individual requirements. So each order needs to be supported by specific auto parts. In reality, however, providing installation instructions to assembly line operators is very challenging. After experimenting with RFID, infrared and barcodes. BMW chose RFID to help operators determine the type of assembly require as each vehicle arrives on the line. They use an RFID-base real-time location system – RTLS. RTLS enables BMW to identify each car as it moves through the assembly line. And not only its location, but all the tools used on that car.

Future Outlook

BMW Group uses a simple automatic identification technology. Such as RFID to realize accurate and rapid identification of object information. Help production factories to make scientific decisions, and improve production efficiency. BMW will target Tesla and continue to expand the application of RFID technology in vehicles. Perhaps in the near future, BMW will also become an excellent new energy vehicle company.