Aviation Industry

The aviation industry is using aviation RFID tag to record maintenance information on critical aircraft components. And other industries are turning to smart tags for asset management and other business applications. These business applications include valves for the manufacturing of remote assets in the renewable energy industry. And production equipment trains for consumer serviceable goods (CPG) manufacturing plants. There are also other means of transport, foreign object damage control. In the nuclear industry and the aviation industry, tools and equipment in the aviation industry. And work-in-progress quality assurance. These industries share some common problems in asset management and MRO.

MRO

Research shows that the technicians in most cases are only productive 20% of the time. 80% of the time is spent gathering information and finding parts and tools. Likewise, assets that are in use or that require periodic maintenance often fail prematurely (reducing economic life). Or miss out on important repairs. These all pose potential dangers to the security of the organization. Other MRO applications that also benefit from high-capacity tags. These include oil and gas exploration, military vehicle and feedstock maintenance, utility pole configuration. And railroad maintenance, among others. Aviation RFID tag make the aircraft safer.

Into Metal

RFIDHY develop the ability to embed UHF RFID tags into metal. Tags for embedded products are a breakthrough in read distance performance, allowing manufacturers to embed them in items as small as bolts. The RFIDHY embedded tag family offers two solutions for metal assets to embed with tags either before or after production. These passive RFID tags have long read distances, relatively small size and robust construction. Because they don’t rely on batteries. Depending on the application, the identification of assets can guaranty for years or decades. With a read distance of up to 6 meters and an application temperature of -40°C to 150°C. It is ideal for RFID solutions that require high-performance tag performance in harsh conditions.

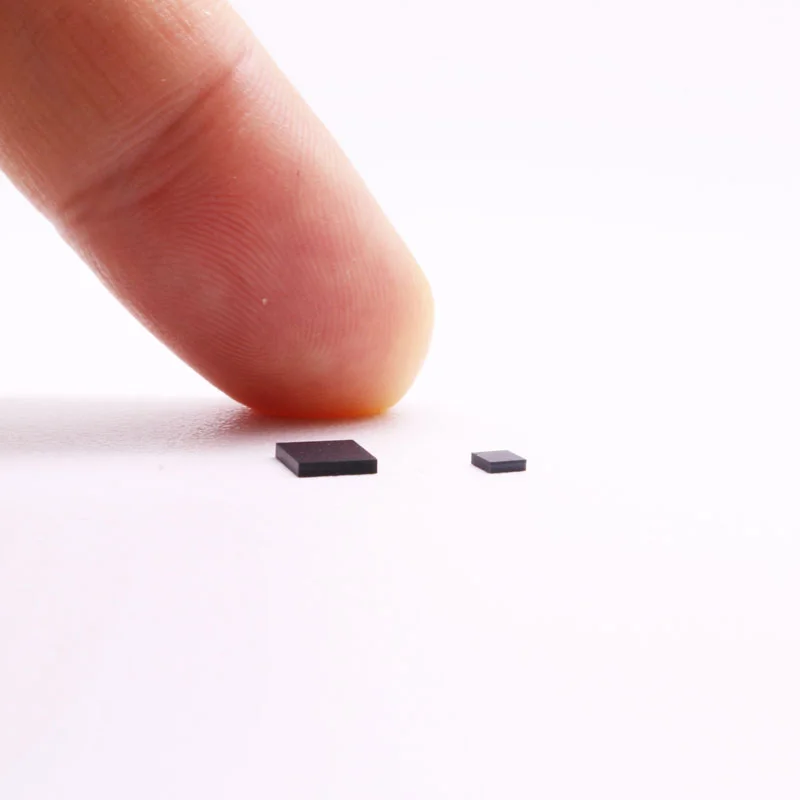

Small Size

These embedded labels are small enough to fit the tool as well as the label. It can provide permanent identification of extremely small-size metal assets. They can also be embedded into metal objects and other assets for extra protection. And still have a read distance of up to 4 meters. RFIDHY series tags can resist high temperature, high pressure and radiation. And other factors that affect the performance of tags and are durable. Label accelerated aging experiments have shown that, under benign conditions. The information within the label can be preserved for 100 years.

Long Term

This tag provides a long-term and safe solution for assets in any environment. Greatly reduces costly product recalls, and facilitates adjustment of tag memory information that needs to be changed due to maintenance. Compared with active tags or pure nameplate identification, high-capacity passive tags are inexpensive to use. And have the advantage of significantly reducing infrastructure and maintenance costs. These tags also do not require batteries and are easier to use than active tags.

Asset Management

Using embedded tags enables smart asset management applications. Asset data pass along with the asset itself, network connectivity, paper reduction, asset visualization. And electronic products that begin to use this to track them throughout their lifecycle. RFIDHY provides reliable RFID tag technology that allows companies to track products from production to retirement. And provide the development of new labels, committed to providing the most robust and durable passive anti-metal surface or embedded technology.