RFID Positioning AGV 2

What is an AGV?

AGV is the abbreviation of Automated Guided Vehicle, which means “Automated Guided Vehicle”. AGV is a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, which can travel along a prescribed guidance path, and has safety protection and various transfer functions. The data acquisition system can collect and monitor the status information and production data in real time, and provide an accurate basic data platform for the production management system (MES/ERP/CIMS).

In the data acquisition system, RFID radio frequency identification is a non-contact automatic identification technology. It automatically identifies the target object and obtains relevant data through radio frequency signals. The identification work does not require manual intervention and can work in various harsh environments. Therefore, its application very broad.

Below, I will share with you

RFID Positioning AGV 3

The use and significance of RFID positioning in AGV car:

The RFID positioning and navigation method can flexibly and conveniently realize the requirements and positioning of the intelligent factory. The AGV car is controlled by PLC, and the car is equipped with a wireless communication system. Therefore, wireless communication with the upper computer can be performed. Report its own running position and working status, and execute the instructions of the host computer. Transfer the work rhythm and workload to the host computer in time. AGV reads ground signs through RFID and makes corresponding actions (changing speed, steering, positioning and parking, etc.). An AGV card reader is installed at the bottom of the AGV body, and an RFID landmark card is installed at the node position on the ground, and an ID number and definition are given to the landmark card on each node. For example, node A represents that the AGV is going to turn, which is represented by ID number 00001. Once the transport vehicle passes by A, the AGV reader will read the electronic tag ID number at A. The PLC makes the trolley make corresponding actions according to the read data, so as to realize the function of the AGV dispatching system and the function of site positioning.

So how does the AGV car achieve intelligent RFID positioning?

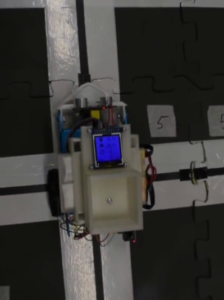

- Install an RFID reader directly below the front of the AGV feeding vehicle. Place pallets, racks, boxes and other goods on the truck for transportation. RFID readers identify RFID landmarks on track nodes to select stations for feeding.

- At the track nodes on the material transportation route, RFID landmarks with site codes are installed. After the material is placed on the AGV feeding vehicle, the control center issues an instruction (transportation route) to the PLC controller. After the PLC receives the instruction, it controls the feeding truck to start and starts to transport the material according to the instruction.

- After the RFID reader identifies the location information stored in the RFID landmark, it feeds back to the PLC controller (control system module). After the PLC receives the encoded data and processes the information, it controls the AGV feeding vehicle to select the station to stop according to the feeding route

- After the material arrives at the station, the AGV feeding vehicle can transport the material to the next station according to the instruction, so after the feeding instruction is completed, the feeding vehicle returns to the starting point according to the set route.

RFID Positioning AGV 4

RFIDHY

As early as 2013, RFIDHY was the first to use the RFID positioning site identification system in the I-SO intelligent AGV.

It leads the innovation of the traditional AGV identification system at the RFID site. RFIDHY independently develops AGV-specific RFID modules and station systems. This system can realize the control and identification of multiple sites. Compared with traditional magnetic landmarks and general high-frequency RFID positioning systems. It has the advantages of strong anti-interference, large amount of information, low power consumption and easy installation. At the same time, the array induction sensor independently developed by RFIDHY is more reliable than the traditional standard sensor. Based on the RFID landmark card positioning method, even in a complex electromagnetic environment, it will not have any impact on our sensor reading.