Medical RFID plays a more and more important role in healthcare. European researchers have developed an RFID-enabled smart bandage. Designed to wirelessly transmit data about the wound healing process based on humidity levels. Reducing the need to remove patient dressings and physically inspect wounds.

Developed by medical RFID researchers at the University of Bologna in Italy. The smart bandage consists of a moisture-sensing material, a built-in UHF RFID chip, an antenna woven into the bandage. And an off-the-shelf leitor de RFID que usa medição de impedância para determinar o nível de umidade através da transmissão RFID. Para saber a saúde da ferida.

Como funciona

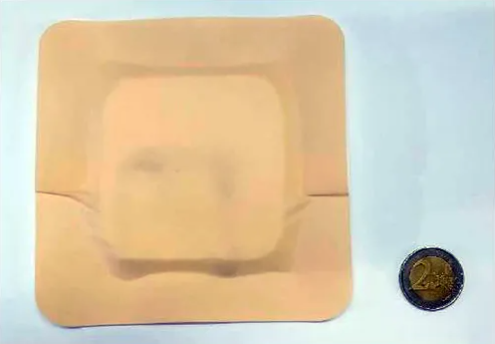

A equipe de pesquisa médica RFID está desenvolvendo protótipos que podem ser impressos em 3D e incorporados em bandagens comerciais. Os pesquisadores também testaram o sistema usando a tecnologia NFC. para que os usuários possam usar um smartphone para capturar dados sem fio sem a necessidade de um leitor RFID dedicado.

Beatrice Fraboni, professor de física da Universidade de Bolonha, disse isso. A longo prazo, the research team hopes to work with tech companies. to commercialize the solution and get approval to start in real patients carry out testing.

Até aqui, Fraboni said, “the group has developed a range of bandages with different numbers of layers and different absorption properties.” Which may vary based on a person’s specific wound and healing requirements. Por exemplo, the burn healing process versus a surgical incision, the healing process of a burn requires some moisture. And moisture in the surgical incision may indicate an underlying infection.

The idea

“The idea is that each type of wound can have its own appropriate dressing.” explains Fraboni, “from slowly exuding wounds to highly exuding wounds.” Traditional wound treatment often requires a doctor and the patient. undergoes a destructive process of dismantling the wound for physical examination. Removing the dressing from the wound often tears the healing tissue and causes secondary damage. And the examination can also be time-consuming for the patient who often needs to visit doctors to examine wounds.

Assim sendo, the research group worked to build a solution that includes wireless smart textiles. The medical RFID bandage is made of a flexible thermoelectric material called poly. (3, 4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS). Which is screen printed on gauze and can be used to identify Changes in humidity. The RFID chip is attached to two antennas that pass through the fabric. The team’s design and engineering work included employing a layer of material that. Once moisture is detected, absorbs and removes liquid so that the next reading can reflect current moisture conditions.

Smart bandage system

The smart bandage system monitors impedance changes based on responses to RFID reader interrogations. The change in impedance depends on the wet and dry state of the antenna. The research team designed the system. So that the reader’s settings can be adjusted based on the magnitude of the impedance. to detect the appropriate sensor values for optimal healing based on various wounds.

Fraboni recalls that developing the system started with a choice of materials. Which they wanted to be biocompatible, disposable and inexpensive.

And PEDOT: PSS satisfies these requirements because it can be screen printed onto two different types of gauze. –artificial gauze and PET gauze. The material reduces potential manufacturing costs and energy requirements associated with manufacturing. And is printed in the middle of the gauze in the form of threads. While two stainless steel conductive threads are stitched onto the conductive coating for use as an RFID antenna. The RFID chip is encoded with a unique ID number, which the reader transmits when interrogated.

benefícios

Fraboni further explained that if the technology could be printed directly on gauze. It could reduce manufacturing costs and environmental impact. Por exemplo, the standard manufacturing process of depositing semiconductor chips into sensor devices. As well as the chemicals and energy used, could be eliminated.

In a typical application, a physician would apply a bandage to a patient’s wound. And the patient would then go home with a leased handheld UHF RFID reader with firmware and settings specific to that wound. Nesse caminho, corresponding thresholds can be set according to the different needs of each patient. And an alert is sent to the doctor when the threshold is exceeded.

The patient is instructed to interrogate the RFID tag built into the bandage at specific time intervals, such as every eight hours. The data will be captured by the reader and can be displayed on the patient’s device screen. While also being transmitted to the relevant physician via a cellular connection. The bandage’s unique ID number is associated with the patient and impedance-based sensor readings. Which can provide doctors with information on how the patient’s wound is healing.

Futuro

While there are already some RFID systems on the market that can detect humidity levels in specific applications. Such as monitoring diapers in hospital environments and detecting leaks in automotive systems. The smart bandages are designed to be more sensitive and can detect anywhere from five to five, Fraboni said. Humidity level of 20 microliters.

atualmente, researchers are working on a prototype. The plan is to build the humidity impedance sensor directly into commercial bandages to provide wound healing management. The next prototype is expected to involve an NFC version of the bandage that can be interrogated via a smartphone. The researchers hope to partner with tech companies to bring their products to the commercial market.