Maybe many friends are not familiar with the term RFID, so let me briefly introduce what RFID is.

RFID (Radio Frequency IDentification, radio frequency identification) is a method of automatically identifying objects. This technology uses radio signals to read or write data stored in RFID tags. Any RFID system consists of readers and transponders (also known as RFID tags).

Most RFID tags consist of two parts

The first is an integrated circuit (IC), which is used for functions such as storing and processing information, modulating and demodulating radio frequency (RF) signals.

The second is the antenna used to receive and transmit signals. With the development of Internet services, known RFID applications have gained additional popularity.

Recently, experts from Shanghai Huayuan Smart have developed a new type of wireless RFID device for the concrete industry. The solution maximizes build production and inventory management processes.

This label makes the reinforced concrete structure traceable throughout its life cycle from production to demolition. The combination of UHF tags and waterproof RFID molded inlays is firmly attached to the concrete structure, and the read and write performance remains stable for a long time.

In addition, inventory management issues are also a long-standing problem in the concrete industry. This is mainly reflected in the quality control of manual processes. Difficulty confirming to the customer that the ingredients of the mixture he ordered are accurate, and the prohibitive cost of recycling and replacement in the event of a problem. RFID concrete tags allow concrete manufacturers to optimize all their production planning and product distribution processes.

Guarantee

RFID data is used to solve quality-related problems and effectively guarantee the correctness of products sent to customers. At the same time, the GPS coordinates of incoming materials are automatically recorded to prepare accurate bills. Additionally, RFID concrete tags allow concrete product manufacturers to provide quality service to contractors and provide them with all the critical information they need when implementing large-scale construction projects.

In addition, it helps to identify concrete and reinforced concrete structures themselves throughout their life cycle, thus guaranteeing the structural integrity and safety of the building.

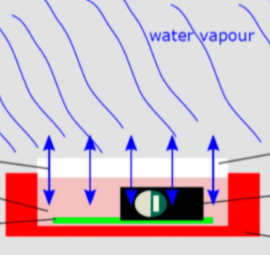

During the production of RFID concrete tags, experts from RFIDHY have overcome many technical obstacles. For example, creating a structure that can be embedded into structural concrete and guarantee the readability of RFID tags. The RF model must be guaranteed to penetrate at least 12 inches of concrete.

After extensive testing in various environments, we have come to the conclusion that Shanghai Huayuan Smart’s UHF RFID concrete tags can be used in various environments such as rainy days. can be read stably from all angles. This gives us confidence that we can provide our customers with a truly powerful RFID building material management solution.