How does RFID industrial tags function?

RFID technology uses radio waves to automatically identify objects, collect data about them, and enter those data directly into computer systems with little or no human intervention. A typical RFID machine has three components: RFID tag, RFID reader and the antenna. RFID cards contain a unique number and other details which is captured by the reader and transformed in to data that gets saved in computers.

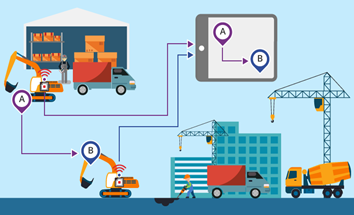

Where is RFID technology applied?

RFID tagging is applied to many industries and work scenarios. The technology is widely being used in apparel, food, logistics, sports, livestock and animal husbandry, medical and many other industries because of the following advantages.

- Long Lasting: The traditional tags and barcodes can get tampered and damaged due to wear and tear. But, RFID tags are highly durable and long lasting. They do not get damaged in harsh environment, heat, dirt and mud.

- Wide range tracking: Traditional tags and barcodes require a reader to manually read each barcode. Whereas, RFID reader can scan multiple tags even from a distance of 100 feet. RFID doesn’t require line of site. This makes the process fast and reliable.

- Data security: The RFID tags have dedicated chip with a unique number that cannot be copied. Traditional systems and barcodes are vulnerable to data breach and recording errors. Anyone can easily duplicate a barcode. RFID tags offer advanced data encryption which hackers cannot copy. It also reduces any chances of missed items when used to collect data on large numbers of items at once thereby minimising chances of a human error.

- Low operating cost: RFID tagging system is less costly and time-consuming than the traditional system. The traditional system involves huge labour cost. Also, the traditional tags need frequent replacements due to wear and tear. RFID tags last for a long time, hence the replacement cost reduces. The economies of scale bring down the operating cost as with the RFID system, a huge stock of goods and assets can be scanned with limited human resource and logistics.

- Shorter process: With Barcode, the reader has to scan each object one by one which makes the process time taking. But, with RFID, thousands of tags can be scanned in seconds reducing the operational time to a great extent. Also, RFID technology can be integrated with other manufacturing and supply chain technologies and the lead time between order to delivery can be reduced considerably.

- Read/write capacity: A barcode is only readable and once printed, the data on the barcode label cannot be changed. But, RFID tags can be read and modified anytime.

- RFID tags store more data: As compared to traditional tags and barcodes. RFID tags can store more data in the non-volatile memory.

- RFID can be applied with barcode: If you are using barcodes and would like to switch to RFID, or would like to use both simultaneously. You can easily attach printable paper labels to RFID tags.

RFIDHY offers variety of RFID enabled tagging solutions for different industries and logistics. We offer UHF, HF and LF RFID tags, suitable for different environments and applications like logistics, inventory and manufacturing management, parking and vehicle access control, laundry management applications, and more. Our industrial tagging products include RFID inlay stickers, cloth tags, NFC tag, waste bin tags, animal ID, RFID coin tag, metal tag and RFID disc tag, dome tag, ceramic tag and many more.